World Chemical News, Circular Economy , Recycle ,

Upcycle by chemwinfo

25 November 2021

INEOS Styrolution confirms its investment decision

for Europe’s first polystyrene advanced recycling pilot plant

Joint collaboration with Recycling Technologies, UK

Europe’s first advanced chemical

polystyrene recycling facility

is expected to be operational

in the second half of 2022

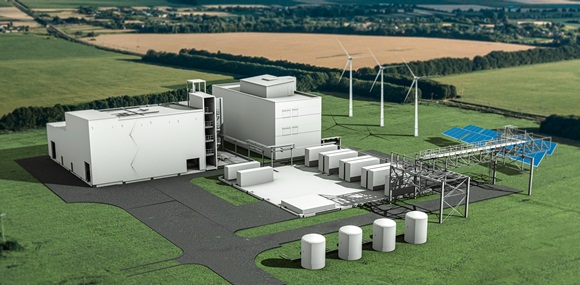

INEOS Styrolution, the global leader in styrenics,

has today confirmed its decision

to invest into a pilot plant

for advanced recycling of polystyrene.

The site will be set up in collaboration with

Recycling Technologies in Swindon, UK.

It is expected to be operational

in the second half of 2022.

The decision announced today is a significant step

forward launching polystyrene recycling

through depolymerisation technology.

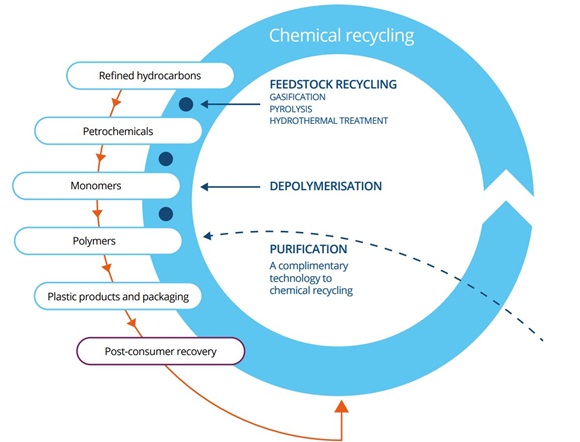

Depolymerisation is an advanced recycling technology

that converts polystyrene waste feedstock

back into its main building block,

Styrene which can then be used

to manufacture new polystyrene

with identical properties to the virgin material.

The unique properties of polystyrene allow

this efficient monomer recycling process

to be harnessed avoiding the need to downcycle polystyrene.

An additional benefit of depolymerisation

is a significant decrease of greenhouse gas emissions

when compared with the production

of virgin polystyrene from naphtha.

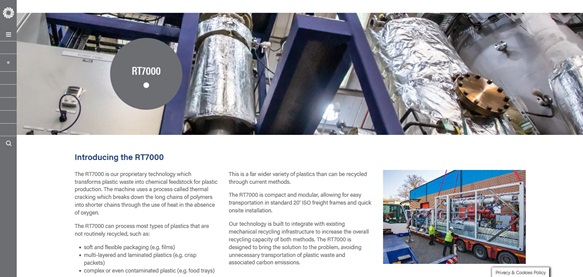

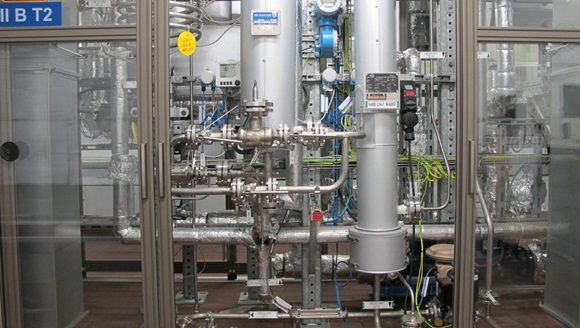

The Swindon pilot plant will be based on

Recycling Technologies’

fluidised bed reactor technology,

which offers excellent scalability

making it the technology of choice

for future even larger recycling plants

Credit > Recycling Technologies

Credit > Chemical Recycling 101

12 July 2021

Cycle for sustainable plastics

Carbon-containing gases from steel production

as a source of raw materials

The objective is to explore

the use of carbon monoxide (CO)

from steel industry metallurgical gases

for the production of high-quality polycarbonates.

Covestro has now commissioned a mini-plant

for this purpose at its Dormagen site.

This is where it is tested whether

the quality of the CO from metallurgical gases

is sufficient for further processing.

The innovative process has great sustainability potential:

Initial life cycle analyses show

that around 0.48 kilograms of CO₂ equivalent

can be saved per kilogram of CO provided

in the steel industry-chemical industry alliance.

This means savings of more than 80 percent.

29 June 2021

BASF to build new battery recycling prototype plant

in Schwarzheide, Germany

Use of innovative technology

for extracting lithium, nickel, cobalt and manganese

from end-of-life lithium-ion batteries

and production scrap

Ensure start-up success for future commercial plants

to enable a circular economy

for the battery value chain

1 June 2021

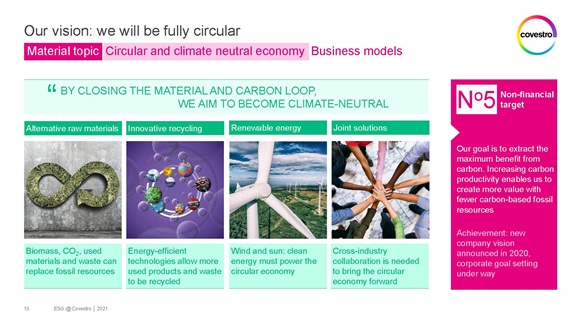

We will be fully Circular by Covestro June 2021

>> Circular Economy – Closing the Loop

27 May 2021

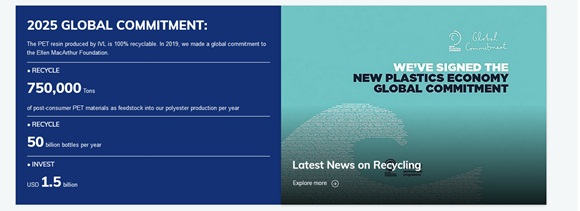

IVL Acquisition of PET Recycling Assets in Texas, USA

Indorama Ventures Public Company Limited

would like to inform that in connection

with an auction conducted pursuant to

the authority of, and governed by

the rules established by,

the Bankruptcy Court in the District of Delaware, USA,

IVL has been selected as

the winning bidder

to acquire

the Recycled Polyethylene Terephthalate (rPET) assets of

CarbonLite Holdings LLC

and its subsidiaries in Texas, USA

(collectively referred to as “CarbonLite”).

CarbonLite is a significant rPET producer in USA

(currently under Chapter 11 of the United States

Bankruptcy Code) with long standing relationships

with major brands.

The assets to be acquired are located in

Dallas, Texas, USA with a combined capacity

of approx. 92 kilotons per annum, consisting of

48 kilotons of rPET pellets and

44 kilotons of flakes.

This proposed recycling acquisition opportunity

would facilitate IVL coming closer to

its rPET commitment of 750 kilotons per annum by 2025.

28 October 2020

_580.png)

Circulytics 2.0 launched

Introducing the new and improved version of

our award-winning circular economy

performance measurement tool.

In January this year, the The Ellen MacArthur Foundation

launched Circulytics —

the most comprehensive tool available for businesses

seeking to measure their circular economy performance.

Since then, more than 600 businesses globally

have signed up to complete a Circulytics assessment —

which has helped them create new strategies

for better growth by adopting

or further embedding circular practices.

One quarter of those businesses

have an annual revenue of more than USD 1 billion.

Earlier this month, Circulytics won

at the Responsible Business Awards 2020,

run by Reuters Events.

Link to The Ellen MacArthur Foundation

10 September 2020

The Ellen MacArthur Foundation launches report:

Financing the Circular Economy - Capturing the opportunity.

Leading investment managers and banks back

over USD 18 trillion in assets under management,

over 30 CEOs and senior executives

from leading asset managers and banks

are backing our latest research,

Financing the Circular Economy-

The endorsers* of the report include

BlackRock, Barclays, Citi, Credit Suisse,

the international business of Federated Hermes,

Lloyds Banking Group, ING, Intesa Sanpaolo,

JPMorgan Chase, Morgan Stanley, Rabobank,

The Ellen MacArthur Foundation works in

Education & Training, Business & Government,

Insight & Analysis, Systemic Initiatives

to accelerate the transition to a circular economy.

>>VISIT ELLEN MACARTHUR FOUNDATION

CREDITS :

WEBSITES OF LEADING CHEMICAL,

PETROCHEMICAL, OIL AND GAS COMPANIES

,WWW.SET.OR.TH,

WWW.BOI.GO.TH

AND LEADING ORGANIZATIONS

WWW.CHEMWINFO.COM BY KHUN PHICHAI