World Chemical News by chemwinfo

5 January 2021

BASF increases prices for its Formulation Additives

globally Effective today,

as existing contracts allow,

BASF is increasing prices globally

for a large part of its Formulation Additives

for paint and coatings industry

such as

Attagel®, Dispex®, Efka®, Foamaster®,

Foamstar®, Hydropalat®, Loxanol®

and Rheovis® grades.

Price increases of up to 5 – 10%

dependent on region are needed

to compensate for increasing costs

from transportation, safety, legislation,

registration requirements (e.g. Reach, TSCA)

and to continue to support customers

with high level products and services

About BASF’s Performance & Formulation

Additives portfolio

BASF is a premiere provider of performance

and formulation additives

for the paints and coatings industry.

With a comprehensive range of respected brands

and a broad technology base of

dispersing agents,

defoamers,

rheology modifiers,

wetting agents

and surface modifiers,

filmforming agents,

light stabilizers,

antioxidants and optical brighteners,

our unique portfolio helps to enable

performance-driven products,

which are passionately designed to meet

the latest and most stringent environmental regulations.

17 December 2020

INEOS signs renewable power deal with RWE

to reduce CO emissions

from its Belgian sites by a further 745,000 tonnes

10 year 56-Megawatt (~200 GWh per annum)

Renewable Power Purchase Agreement

Renewable electricity goes direct

to INEOS sites in Belgium.

Advances emission reductions at INEOS sites

in Belgium to nearly 2 million tonnes of CO

Forms important part of the INEOS roadmap

for a reduction in carbon-based energy for its facilities.

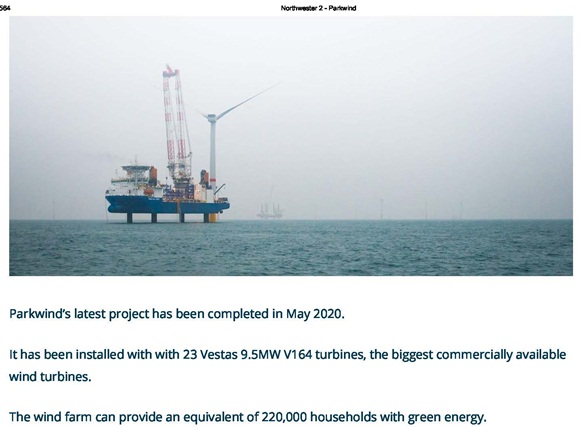

INEOS has agreed a long term Power Purchase Agreement

for renewable offshore wind power

in Belgium with RWE.

Under the terms of the ten-year deal,

which begins in 2021, INEOS will purchase

56-Megawatt (198 GWh per annum)

of off-shore wind power from

RWE Supply &Trading,

produced at the Northwester2 wind park

in the Belgian North Sea.

This significant deal will take

ca. 25% of Northwester2’s renewable electricity.

It will reduce the carbon footprint of INEOS

in Belgium by a further 745,000 tonnes of CO2

over the length of the contract,

which is the equivalent of

taking 65,000 cars off the road each year.

This is the second renewable power deal

agreed by INEOS as part of our road map

to reduce greenhouse gas emissions

from across its operations,

as the company continues to supply

essential products that people increasingly need

across medical, food, transport and construction.

Combined with the Norther deal announced in September

with Engie, the agreement with RWE

increases the INEOS commitment to

Belgian offshore renewable wind to 140 MW

(~500 GWh per annum).

Together this reduces

the carbon footprint of its operations

by nearly 2 million tons of CO2

over the life of the contracts;

the equivalent of taking more than 160,000 cars

off the road each year.

16 December 2020

Solvay decarbonizes production at its Melle plant

in France.

Solvay has begun a process of decarbonizing

the cyclopentanone unit of its Melle plant in France.

Through an agreement with an agricultural cooperative

for the next fifteen years,

the entire cyclopentanone production

already relies solely on biomethane gas,

a green source of energy.

The cooperative built a facility to convert

waste biomass into18 GWh

of renewable natural gas (RNG) per year,

which Solvay has committed

to purchase for its Melle plant.

Guillaume Meunier,

Flavor & Fragrance Global Market Director

for Solvay Aroma Performance

“Powering the Melle plant with biomethane gas

is a part of our Solvay ONE Planet initiative,

which aims to

reduce greenhouse gas emissions by 26% by 2030.”